Construction begins on new Shell plant in Wesseling

New Base Oil Distillation Unit (BODU) enables production of high quality base oils up to medical white oil purity level

As long-standing partners of Shell, Kraftanlagen and ECM are awarded the contract for the pre-engineering and construction of the new BaseOil distillation unit

The construction of the new R3 base oil plant at the Shell Energy and Chemicals Park Rheinland (Shell Rheinland) was launched with an internal ceremony. The project is being implemented by Kraftanlagen Energies Services SE – a subsidiary of Equans, a leading global company in the energy and services sector. Kraftanlagen has been appointed general contractor for the realisation of the project. Engineering and project management will be carried out by ECM, a wholly owned subsidiary of Kraftanlagen.

”We have been working with Kraftanlagen for many years. In awarding the contract for the R3 Base Oilproject, we were particularly impressed by the industrial services provider's expertise in the field of decarbonisation and its geographical proximity. With Kraftanlagen as a partner, we can be sure that we will have experienced specialists and qualified installation personnel on site at all times, both during the planning phase and at the end of the project.”

Amu ArenjaProjektleiter bei Shell

Shell has set itself the goal of becoming a net-zero emissions company by 2050. This also applies to Shell Rheinland in the south of Cologne. As part of this transformation, the site is being transformed from a crude oil refinery into a production site for sustainable energy and chemical products. In addition to sustainable, high-quality lubricants, these include, for example the production of hydrogen from renewable energies or bio-LNG as a fuel for heavy goods transport.

The R3 Base Oil project plays a key role in this transformation. It aims to modify the hydrocracker that currently produces base products for fuel distillation. A new base oil distillation unit will produce high-quality, pure base oils that meet the highest standards and can be used, for example, in medical and cosmetic applications or as more sustainable lubricants in mobility. This allows the hydrocracker to be used intelligently in the long term, even in times of energy transition. The new product portfolio resulting from the modification strengthens Shell Rheinland’s economic power and, thanks to the inno-vative technology, sustainably reduces CO2 emissions.

”We are delighted to be able to support Shell in this transformation process. With our expertise in project management and our experience as a general contractor, our customers receive everything from a single source - from planning to commissioning and handover.”

Florian ObermayerLeiter der Business Unit Industrie bei Kraftanlagen Energies & Services

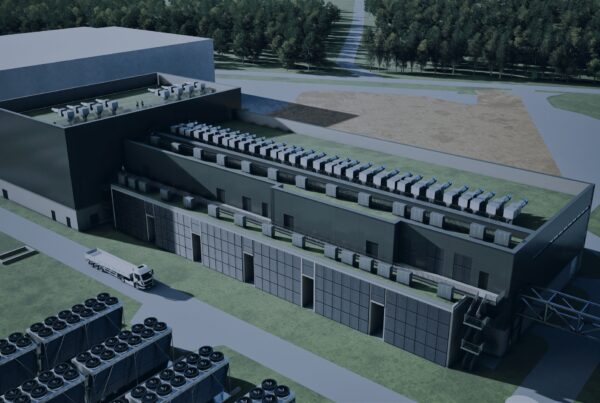

The new Base Oil Distillation unit (BODU) at the Wesseling site enables to produce high-quality base oils. ©Shell Deutschland

The construction of the new R3 base oil plant at the Shell Energy and Chemicals Park Rheinland was launched with an internal ceremony.

From left to right: Amu Arenja, Senior Project Manager Shell Germany, Florian Obermayer, Business Unit Manager Industry Kraftanlagen Energies Services, Marijn Bezuijen, Project Director Rheinland Shell Germany, Christian Wanghofer, Project Manager Kraftanlagen Energies Services. ©Shell Deutschland

Press contacts

Dr. Isabelle Werner +49 89 6237 387, isabelle.werner@kraftanlagen.com

Verena Treutlein +49 89 6237 627, verena.treutlein@kraftanlagen.com

Here you can download the press release as Pdf file.