[color: #4a4a49; color=””]C[/color: #4a4a49;]ombined Heat and Power plants (CHP units) are remarkably efficient power generators because they produce electrical power and heating simultaneously. This makes them ideal for the decentralised supply of power to buildings of all kinds, including industrial plants and companies that wish to generate their own power independently of the public grid.

Which is why Kraftanlagen has specialised in the planning, construction, maintenance and modernisation of power plants, including large ones, all based on the CHP principle. Furthermore, the energy concept of municipal utilities enables domestic households to be supplied as well.

An extensive and complex refurbishment project is now approaching successful completion at the Stonsdorf site operated by Stadtwerke Norderstedt. Stadtwerke has commissioned a full CHP update using the very latest technology for a plant constructed 13 years ago by Kraftanlagen that has been connected to the town’s public grid since that time. As part of its modernisation efforts, Stadtwerke Norderstedt is having its CHP sites renovated. This with the aim of making the operation of its plants more efficient and also more CO2-neutral in future.

CHP plant in Stonsdorf now more efficient with heat pump In 2011, Kraftanlagen built a single-storey gas engine plant with an electrical output of 2 MW here. The conversion concept involved extending the building by a further storey. The technical extension consists of two heat pumps, which increase the efficiency of the overall system in CHP operation. This is made possible by the exhaust gas from the gas engine, which is cooled down to 20 degrees, whereas previously it was cooled down to 70 degrees. The result is an additional 500 kW of thermal output available for the heat pump system. With the use of electrical energy, around 800 kW of additional power can be supplied to the district heating system by the heat pumps in this way.

Significantly higher efficiency thanks to heat pump and recirculating air cooling At the same time, another source is used for the heat pump system. The room air heated by the radiant heat from the unit is fed through a recirculating air cooling coil on the upper floor of the building and then cooled and fed back into the unit room. In this way, the radiant heat from the unit becomes useful heat and is also fed into the district heating network of the municipal utilities via the heat pump. In the genset room, only the combustion air is fed in as supply air.

“Stand-alone operation” with heat pump possible But that’s not all: when the CHP plant is not running, the heat pump system operates in “stand-alone” mode and uses an air cooler system located on the roof of the building as a heat source. This enables the municipal utilities to supply the connected households with district heating at a flow temperature of up to 80 degrees even without operating the gas engine – and completely from renewable sources.

Technical data of the CHP in Stonsdorf, Norderstedt

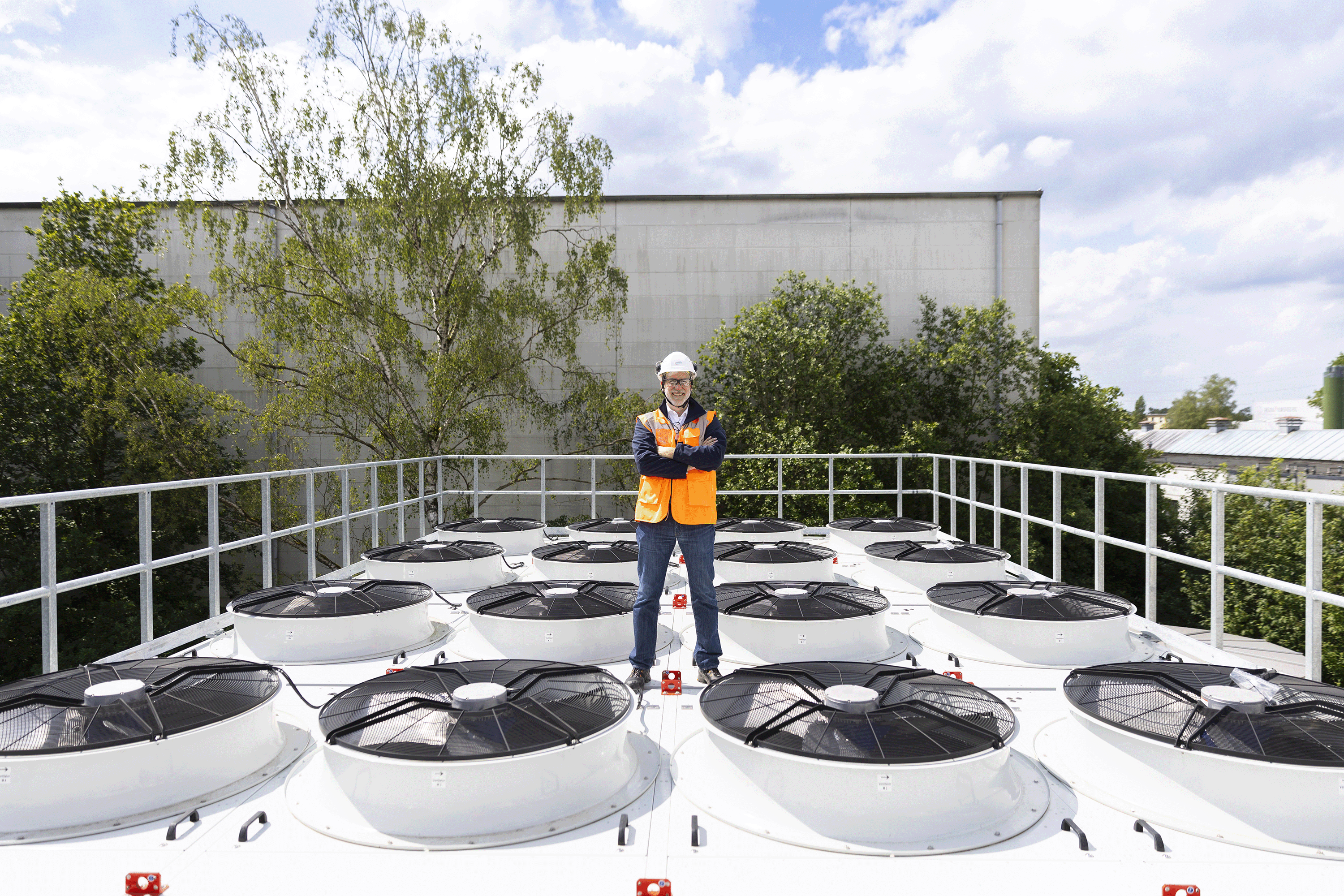

Martin Heimann, Head of Sales Decentralized Energy Systems at Kraftanlagen Energies & Services SE, and Steffen Blohm, erector at Kraftanlagen Energies & Services SE, at the Stonsdorf CHP plant © Cyril Abad

Previously, with similarly extensive conversion measures, Kraftanlagen had modernised the CHP systems operated by Norderstedt Stadtwerke at its Buchenweg and Nord sites. Taking the Buchenweg site as an example, a heat pump is supplied from the engine exhaust gas. This has increased the overall efficiency rating of the CHP plant (here too) to 106 per cent (thermal: 68.9 percent, electrical: 37.6 percent). Here too, measures were taken to achieve two objectives. These were to increase efficiency while at the same time reducing CO2emissions. The town of Norderstedt is pursuing ambitious targets, in relation to both the ‘electricity transition’ and the ‘heating transition’. The town now operates three CHP plants and refurbishment of these is a key element in achieving these targets: the addition of heat pumps has increased the efficiency ratings at all three locations.

In the long term, these refurbishment measures will help to achieve output compliant with a 1.5-degree target through a focus on the generation of CO2-neutral electricity coupled with the use of renewable substitutes for natural gas.

Excursus: Why CHP plants are an important pillar ofCO2 reduction and therefore key factors in the energy transition The energy transition requires a large-scale modernization of current heating systems. Less efficient heating systems based on the burning of fossil fuels must be replaced by more intelligent systems on a large scale. Combined heat and power plants are an essential component of such decentralized energy concepts. As they generate electricity and heat at the same time and follow the principle of combined heat and power generation, they are characterized by their high efficiency, which is up to 97 percent (the efficiency of conventional CHP units is usually 80 to 90 percent). In particular, CHP units that are operated with non-fossil and renewable fuels make a significant contribution toreducing CO2 emissions. By feeding electricity and heat into public electricity and heating grids, CHP units can help to avoid transmission losses and stabilize public electricity grids. Through decentralized energy generation, they also contribute to the stability of the power grid, especially during peak times. In addition, CHP units enable greater integration of renewable energies into the energy supply system if they are operated with non-fossil and renewable fuels.

CHP types based on different technical solutions and dimensions

- The most widespread are (still) what are referred to as engine CHPs, in which conventional petrol engines are used to operate a generator that in turn produces heat and power.

- Instead of an engine, the CHP plant is driven by a gas turbine. The disadvantage of these CHP systems is that they produce less power (electricity) but they are more effective at generating heat.

- The principle of the steam turbine CHP is based on the steam generated during combustion. This steam is then used to drive a very powerful turbine.

- If required, the Stirling engine CHP can also be operated with pellets or wood chips. Although the efficiency rating of the Stirling engine concept is not that great, it does help to reduce CO2 levels, provided it is not operated with gas.

- Fuel cell CHPs are not yet in widespread use. Here, heat and power are produced by triggering an electrochemical reaction, e.g. by using hydrogen as fuel. This concept has a climate-neutral ecological footprint.

- Nano-CHPs are systems that generate less than 2.5 kW of power and less than 12 kW of heat. They are most frequently used in smaller residential buildings.

- A micro-CHP is one with a maximum power generation of 15 kW and a maximum thermal output of 30 kW. These are a popular choice for small businesses or multiple-occupancy residential buildings.

- The mini-CHP variant is defined by the generation of up to 50 kW of electrical power and 100 KW of heating. Large residential buildings and medium-sized companies are the most frequent users of this type.

- With output data in the MW range, these are the kind of (large) CHP units commonly used by municipal utilities or industrial companies.

Martin Heimann, Head of Sales Decentralized Energy Systems at Kraftanlagen Energies & Services SE, on the roof of the CHP plant in Stonsdorf © Cyril Abad

Why decentralized energy supply is so important for climate change Kraftanlagen is the specialist for decentralized energy supply concepts. Decentralized energy supply essentially means that electricity and energy are produced in a CHP unit, for example, exactly where they are needed. CHP units are based on the principle of combined heat and power generation. Combined heat and power generation is the conversion of energy from a combustion process into mechanical or electrical energy with the simultaneous provision of usable thermal energy in one process. The heat produced in parallel to the electricity generation is used for heating and hot water or for production processes. Thanks to the CHP principle, the fuels used are used multiple times to generate energy with high levels of efficiency, ideally while minimizing CO2 emissions at the same time. A conventional CHP unit generates electricity by means of a combustion engine, during the operation of which the resulting waste heat is used, for example, to feed a district heating network.

Decentralized energy management If households obtain their heat and electricity from a CHP plant operated by their municipal supplier, for example, this has a major impact on the ecological balance of their own region. This requires closed distribution networks and a decentralized energy supply that is based on renewable energies and is part of a decentralized energy management system. Ideally, the most important components of a CHP unit are engines that do not consume fossil fuels such as gas or oil, but run on renewable fuels. Virtual power plants”, which are a combination of different, decentralized energy generators, can also be part of decentralized energy management. Kraftanlagen specializes in planning, building and maintaining such complex systems. The components of a contemporary system for decentralised power generation:

- Combined heat and power plant

- Gas turbines

- Combined heat and power system

- Internal combustion engines

- Heat accumulators

- Heat exchangers

- Heat pumps

Kraftanlagen is your development partner for decentralised energy supply concepts, or for decentralised power supplies, serving systems from 1 MW. We are able to plan and design your decentralised system, creating precisely the combination of components that will enable you to achieve your goals safely while also making an active contribution to climate change, and of course providing a secure supply of heat and power.

CHP plant in Stonsdorf © Cyril Abad